Product Information »

WEB Catalog

»

Air Cylinders

»

Mechanically Jointed Rodless Cylinders

Mechanically Jointed Rodless Cylinders

Mechanically Jointed Rodless Cylinder MY1

-

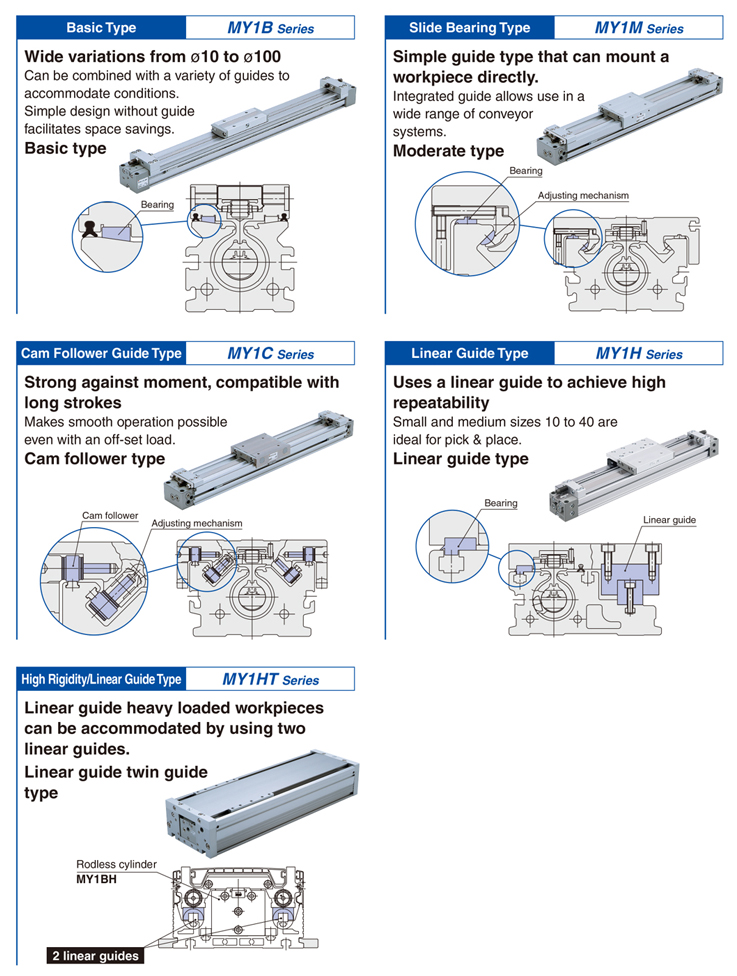

・With 5 standardized guide types

・A variety of applications are available based on the load mass and required accuracy.

Safety Instructions

Actuators/Precautions

Auto Switches/Precautions

Model Selection/Technical Data

Quick Selection Tables

Made to Order Common Specifications

Green Procurement (RoHS)

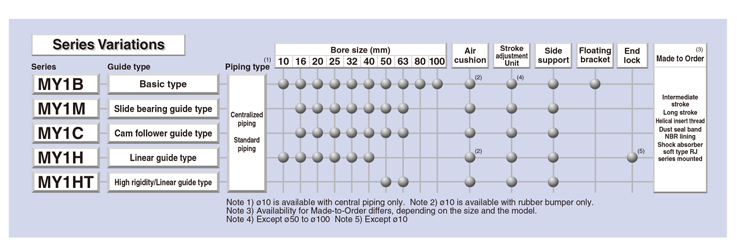

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Basic | MY1B | Double acting | 10,16,20,25,32,40,50,63,80,100 |

| Slide bearing | MY1M | Double acting | 16,20,25,32,40,50,63 |

| Cam follower guide | MY1C | Double acting | 16,20,25,32,40,50,63 |

| Linear guide | MY1H | Double acting | 10,16,20,25,32,40 |

| Linear guide | MY1HT | Double acting | 50,63 |

Features

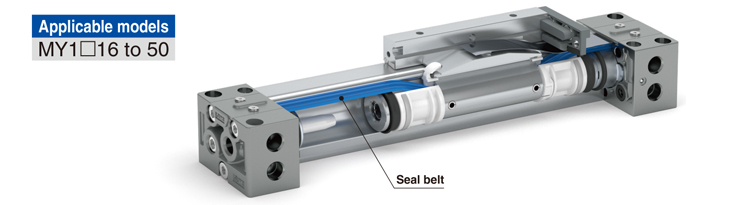

■Minimal leakage seal construction

The flexible material of the seal belt allows for improved adherence to the cylinder tube, resulting in a reduced leakage amount.

(50% reduction compared with the current product)

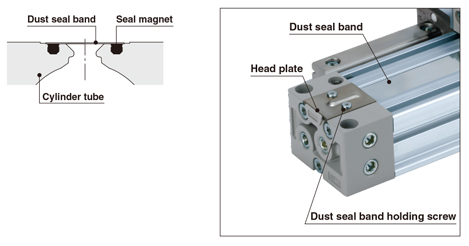

■Dust seal band with improved holding force

The seal magnet on the cylinder tube adsorbs the dust seal band with magnetic force, resulting in improved holding force.

The dust seal band can be easily removed for replacement by simply loosening the two holding screws.

Easier maintenance

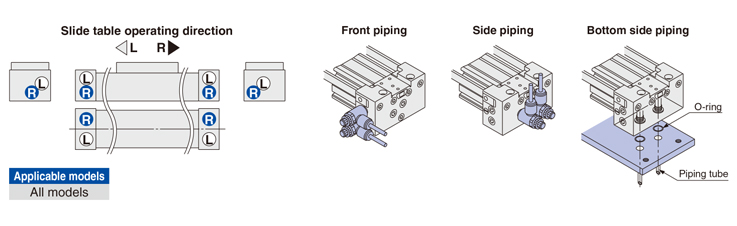

■Allows for piping to be connected according to installation conditions. Centralized piping type for increased piping freedom

■MY1M and MY1C compatibility guaranteed

With the same outer dimensions and workpiece mounting dimensions, both series are compatible with stroke adjustment units, side supports, auto switches, etc.