WEB Catalog

Product List

- Air Management System

-

Directional Control Valves

- Pilot Operated 4/5 Port Solenoid Valves

- Pilot Operated 3 Port Solenoid Valves

- Direct Operated 3/4/5 Port Solenoid Valves

- Reduced-wiring Fieldbus System (Serial Transmission System)

- Air Operated Valves

- Mechanical Valves/Transmitters

- Finger Valve/Hand Valves/Residual Relief 3 Port Valve

- Blow Guns

- Power Valves

- ISO Valves

- Explosion-Proof Valves

-

Air Cylinders

- Standard Air Cylinders (Round Type)

- Standard Air Cylinders (Square Cover)

- Compact Air Cylinders

- Environment Resistant Cylinders

- Floating Joints/Rod End

- Air-hydro Units

- Mechanically Jointed Rodless Cylinders

- Magnetically Coupled Rodless Cylinders

- Table Cylinders

- Guide Cylinders

- Dual Rod Cylinders

- Lock Cylinders/Cylinder with An End Lock

- Fine Lock Cylinders

- Specialty Cylinders

- Clamp Cylinders

- Pin Shift Cylinder

- Stopper Cylinders

- Stroke Reading Cylinders

- Valve Mounted Air Cylinders

- ISO Cylinders

- Shock Absorbers

- Auto Switches

- Actuator Position Sensor

- Rotary Actuators/Air Grippers

- Electric Actuators/Cylinders

- Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other)

- Air Preparation Equipment

- Modular F.R.L./Pressure Control Equipment

- Lubrication Equipment

- Fittings and Tubing

- Flow Control Equipment

- Silencers/Exhaust Cleaners/Blow Guns/Pressure Gauges

- Switches/Sensors/Controller

- Static Neutralization Equipment

-

Industrial Device Communication Equipment/Wireless System

- Wireless System: PROFINET Compatible Products

- Wireless System: EtherNet/IP Compatible Products

- Wireless System: IO-Link Compatible Products

- Wireless System: CC-Link Compatible

- Industrial Device Communication Equipment: PROFINET Compatible Products

- Industrial Device Communication Equipment: EtherNet/IP Compatible Products

- Industrial Device Communication Equipment: EtherCAT Compatible Products

- Industrial Device Communication Equipment: Modbus TCP Compatible Products

- Industrial Device Communication Equipment: ETHERNET POWERLINK Compatible Products

- Industrial Device Communication Equipment: CC-Link IE Field Compatible Products

- Industrial Device Communication Equipment: SSCNET III Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅲ Compatible Products

- Industrial Device Communication Equipment: PROFIsafe Compatible Products

- Industrial Device Communication Equipment: IO-Link Compatible Products

- Industrial Device Communication Equipment: PROFIBUS Compatible Products

- Industrial Device Communication Equipment: DeviceNet Compatible Products

- Industrial Device Communication Equipment: CC-Link Compatible Products

- Industrial Device Communication Equipment: AS-interface Compatible Products

- Industrial Device Communication Equipment: CANopen Compatible Products

- Industrial Device Communication Equipment: CompoNet Compatible Products

- Industrial Device Communication Equipment: Interbus Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅱ Compatible Products

- Other: RS232C Compatible Products

- Other: RS485 Compatible Products

- Process Valves

- Chemical Liquid Valves/Fittings & Needle Valves/Tubing

- Process Pumps(Diaphragm Pumps)

-

Temperature Control Equipment

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Dual Channel Thermo chiller for Lasers

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers)

- Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

- Air Temperature Controllers

- Process Gas Equipment

- High Vacuum Equipment

- Industrial Filters/Sintered Metal Elements

- Pneumatic Instrumentation Equipment

- Hydraulic Equipment

Theme

-

Clean Series/Low-Particle Generation

- Directional Control Valves

- Air Cylinders

- Rotary Actuators

- Air Grippers

- Air Dryers

- Compressed Air Cleaning Filter Series

- Clean Gas Filters/Air Filters

- Exhaust Cleaner for Clean Room/Clean Exhaust Filter

- Modular F.R./Pressure Control Equipment

- Fittings

- Tubing

- Flow Control Equipment

- Switches/Sensors

- Flow Switch

- Electric Actuators

- Fluoropolymer Equipment/PVC Equipment

-

Series Compatible with Secondary Batteries Series 25A-

- Directional Control Valves

- Actuators

- Related Products

- Rotary Actuators/Air Grippers

- Vacuum Equipment

- Air Preparation Equipment/Clean Air Filters

- ModularF.R.L./Pressure Control Equipment

- Flow Control Equipment/Fittings

- Tubings

- Detection Switches/Auto Switches

- Process Valves

- Process Gas Equipment

- Electric Actuators

- Copper, Fluorine-free Equipment Series 20-

- ISO Products

- Arc Welding Process Equipment

- IO-Link Devices

- List of ATEX Compliant Products

Auto Drains/Differential Pressure Gauges

Auto Drain Valve AD402-A

-

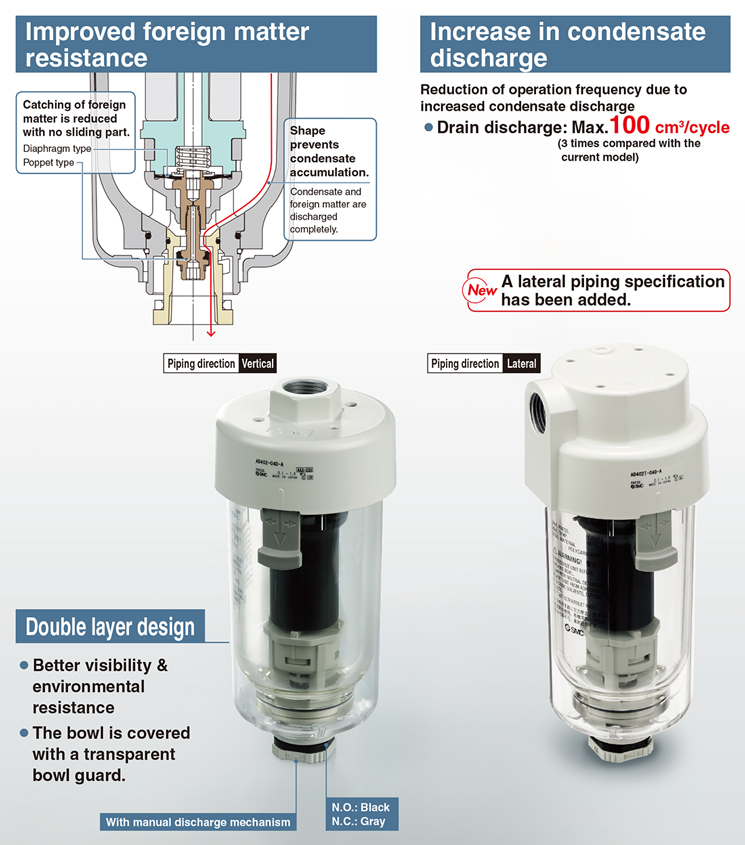

・Improved foreign matter resistance

・Increase in condensate discharge

Drain discharge: Max. 100 cm3/cycle (3 times that of the existing model)

・Improved environmental resistance: Transparent bowl guard can protect the inner

bowl

・Improved visibility: 360°

・Lightweight: Weight reduced by 22%

・Reduced required maintenance space

・Easier maintenance

One-touch mounting and removal of the bowl is possible without using any tools.

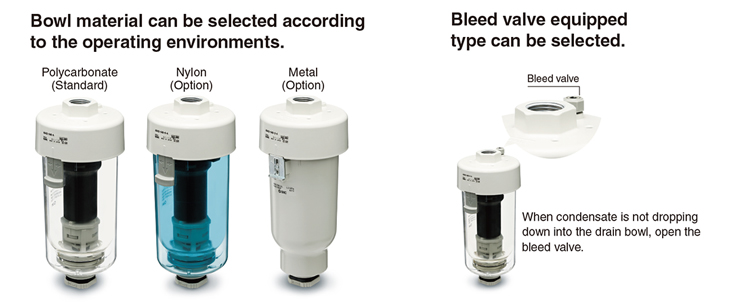

・Bowl material can be selected according to the operating environment.

-

2D/3D CAD

The new SMC CAD SYSTEM, CADENAS, allows you to output 2D/3D CAD data with full part numbers in various data formats. Responses to part number selection has been greatly improved with the newly developed system.

Click here for 2D/3D CAD2D CAD

Click here for 2D CAD

| Series | Port size | Drain port size |

|---|---|---|

| AD402-A | 1/4, 3/8, 1/2 | 3/8 |

Features

Longer life & Higher resistance to foreign matter

Lightweight

Resin bowl guard has reduced the weight by 22%

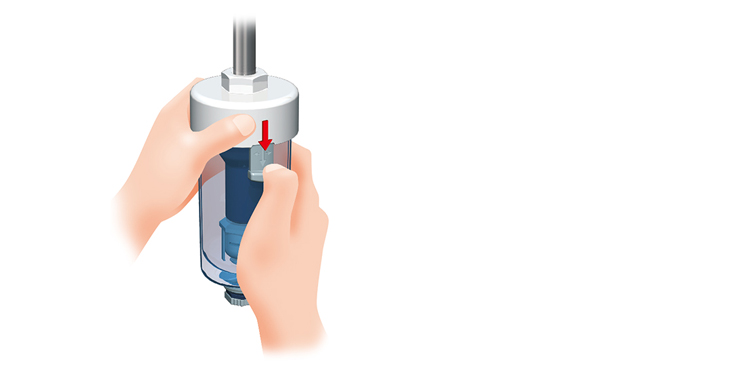

Easier maintenance

One-touch mounting and removal of the bowl is possible without using a tool.

Release the lock by sliding the lock button down while holding the body.

Then, rotate the bowl guard and pull down for removal.

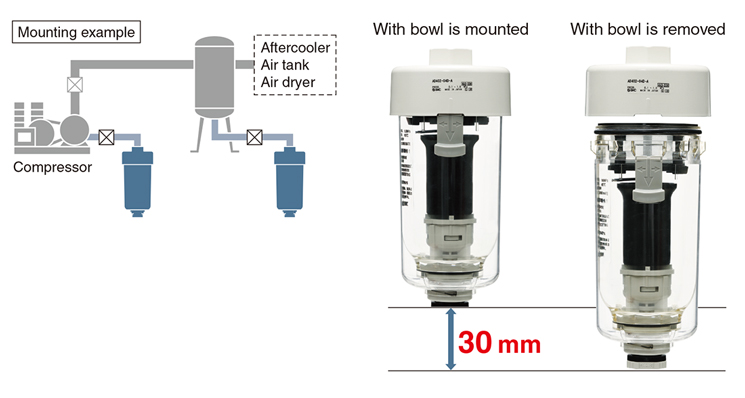

Reduced required maintenance space

Only 30 mm of space is required underneath for maintenance, allowing more compact installation.

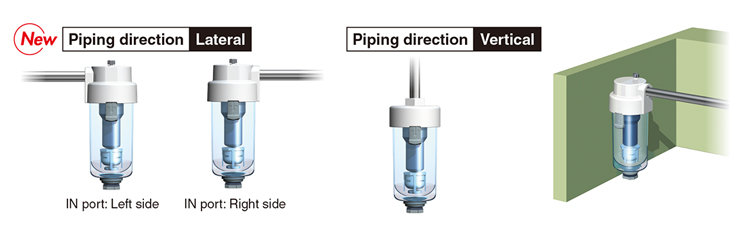

Selectable piping direction

Transparent bowl guard

Better environmental resistance: Transparent bowl guard can protect theinner bowl!

Windows on the bowl guard have been removed and the inner bowl isinstead covered with a polycarbonate transparent bowl guard. Now, even ifthe environment changes and the bowl is exposed to corrosive chemicalor oil splash, the foreign matter will not stick directly to the pressurizedbowl. This can reduce risk of bowl breakage.

Options