Pilot Operated 4/5 Port Solenoid Valves

5-Port Solenoid Valve VQC4000/5000

-

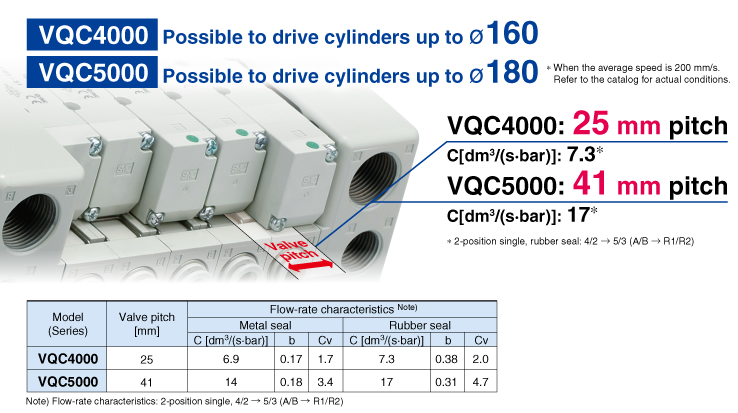

・Compact with a large flow capacity

VQC4000: Can drive cylinders up to ø160

VQC5000: Can drive cylinders up to ø180

・An extensive range of protocols are available.

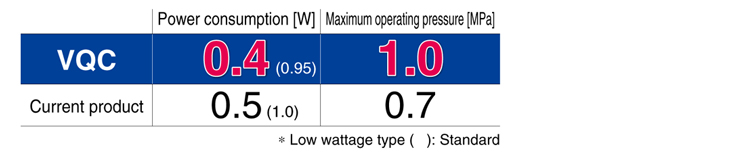

・Power saving: Power consumption of 0.4 W (Low wattage type)

・Enclosure IP67 compliant

・Supports Interface regulators

| Series | Flow rate characteristics 4/2→5/3(A/B→EA/EB) C[dm3/(s・bar)] |

Flow rate characteristics 4/2→5/3(A/B→EA/EB) b |

Flow rate characteristics 4/2→5/3(A/B→EA/EB) Cv |

Applicable cylinder size |

Power consumption (W) |

|---|---|---|---|---|---|

| VQC4000 | 7.3 | 0.38 | 2.0 | φ160 | 1.0 0.4(Low wattage type) |

| VQC5000 | 17 | 0.31 | 4.7 | φ180 | 1.0 0.4(Low wattage type) |

Features

Compact and large flow capacity

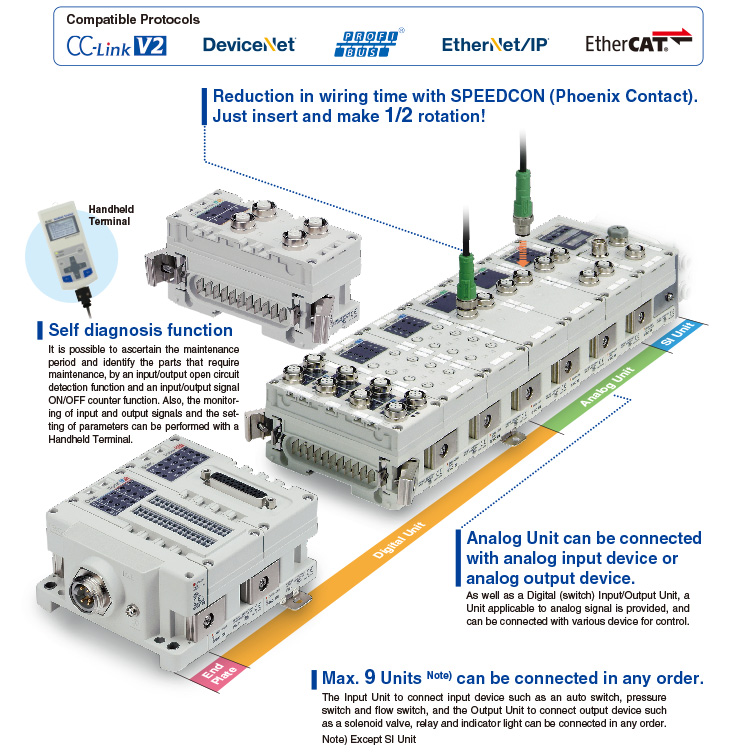

Extensive range of protocols available

Long service life: 100 million cycles

∗ According to SMC life test conditions

Enclosure IP67 compliant

∗ Except F and P kits

Applicable to EX600 (Input/Output) serial transmission syste

(Fieldbus system)

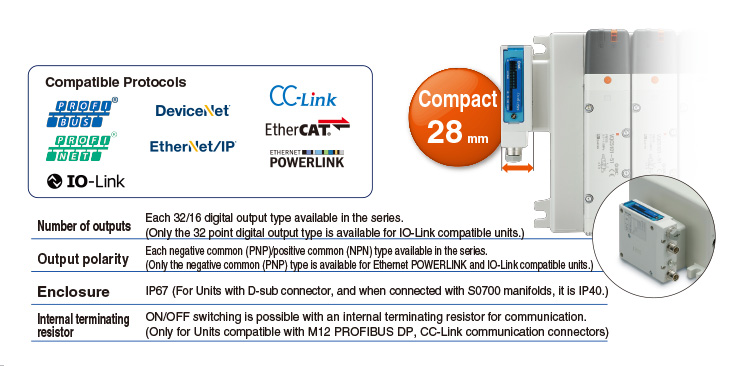

EX260 (Output device for driving 5 port solenoid valves)

The EX260 series supports safety communication (PROFIsafe).

・This is a Fieldbus unit which supports safety standard ISO 13849-compliant safety circuit constructions.

・Using the safety communication protocol

Refer to the EX260 Web Catalog for details on units that support the safety communication protocol.

When using a manifold valve within an ISO 13849-compliant safety system, the device needs to be considered from both the pneumatic circuit and the electric side.

Devices (including valves) need to be selected based on whether their functions are in line with the safety level of the equipment as a whole.

The use of valves that have been validated as being compliant with ISO 13849-2 may be required.

For details on valves that have been validated, please contact SMC.

In addition, refer to “Safety Instructions” for precautions on model selection.

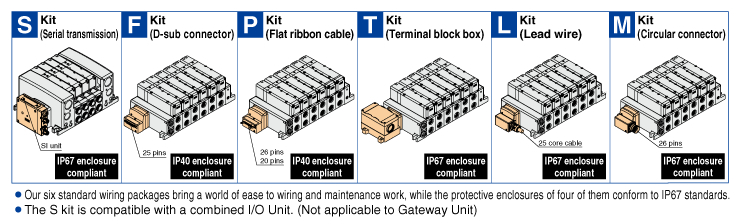

A wide variety of prepackaged wiring configurations

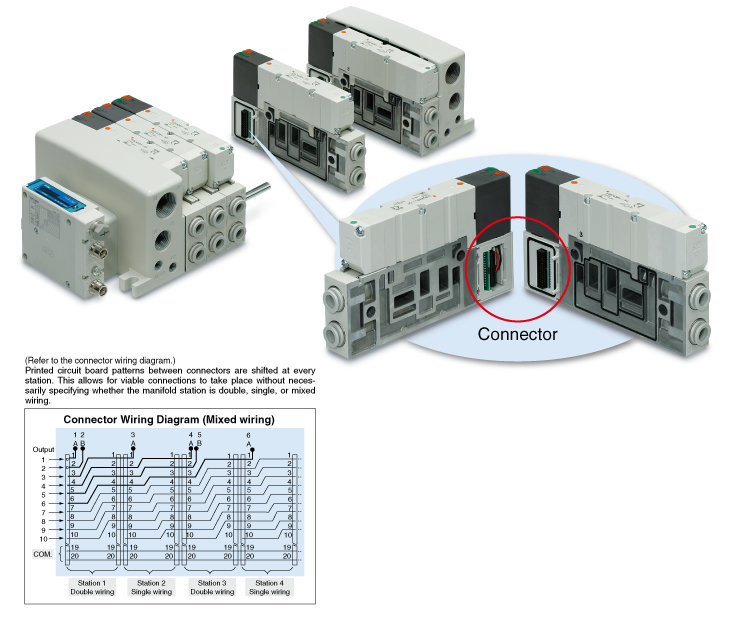

Connector type manifold

●The use of multi-pin connectors to replace wiring inside manifold blocks provides flexibility when adding stations or changing manifold configuration.

●All kits use multi-pin connectors, so switching from the F kit (D-sub connector) to the S kit (serial transmission) can be done simply by changing the kit section.

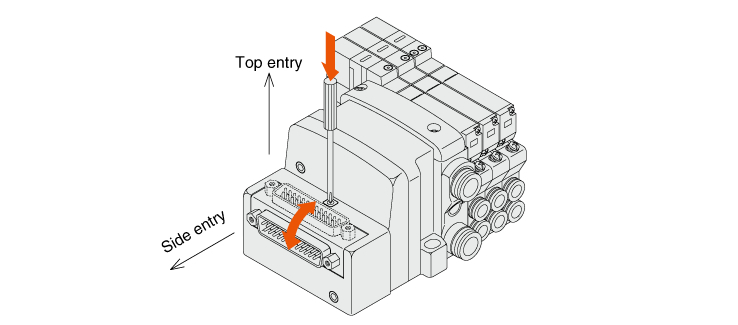

Connector entry direction can be changed with a single push. (F/P kit)

The connector entry direction can be changed from the top to the side by simply pressing the manual release button.

It is not necessary to use the manual release button when switching from the side to the top.