Other: RS232C Compatible Products

Thermo-chiller/Dual Channel Thermo-chiller for Lasers HRL

-

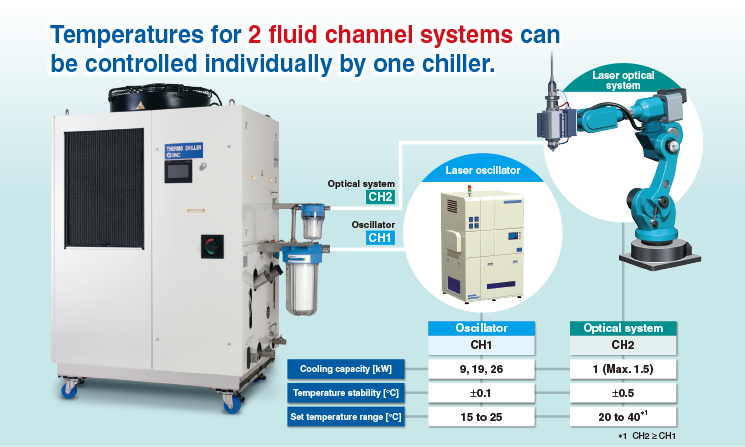

・Temperatures for 2 fluid channel systems can be controlled individually

by one chiller.

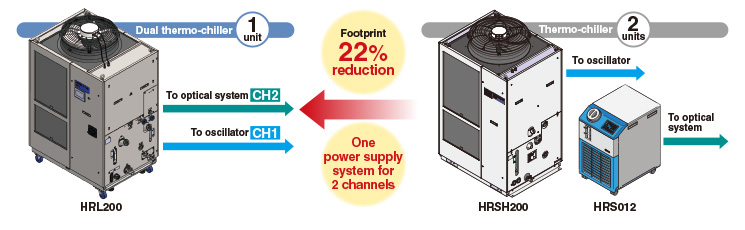

・Space saving, Reduced wiring

Footprint: 22% reduction

One power supply system for 2 channels

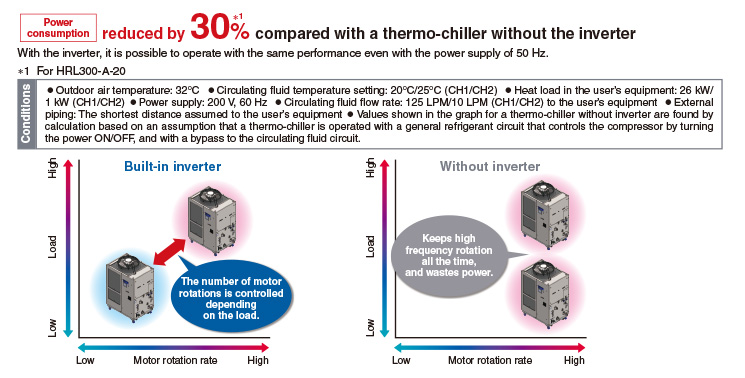

・Energy saving

Power consumption reduced by 30%

・Touch panel

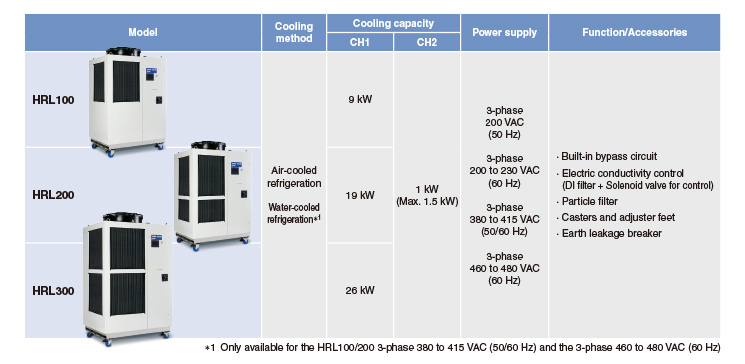

・Power supply:

3-phase 200 VAC (50 Hz)

3-phase 200 to 230 VAC (60 Hz)

3-phase 380 to 415 VAC (50/60 Hz)

3-phase 460 to 480 VAC (60 Hz)

| Series | Set temperature range |

Cooling capacity |

Temperature stability |

Cooling method | Circulating fluid |

|---|---|---|---|---|---|

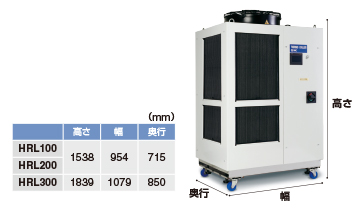

| HRL100 HRL200 HRL300 HRL400 |

CH1: 15 to 25℃ CH2: 20 to 40℃ |

CH1:9 kw, 19 kW, 26 kW, 37kw CH2: 1.0 kW (Max. 1.5 kW) |

CH1: ±0.1 CH2: ±0.5 |

Air-cooled refrigeration Water-cooled refrigeration |

Tap water, Deionized water |

Features

Temperatures for 2 fluid channel systems can be controlled individually by one chiller.

Space saving, Reduced wiring

-

Space saving

Keeping the size similar to the (HRSH series) single chiller, the temperature of 2 fluid channel systems are controlled individually.

-

Reduced wiring/labor

One power supply system for temperature control of 2 channels Less work-hour for wiring

Energy saving

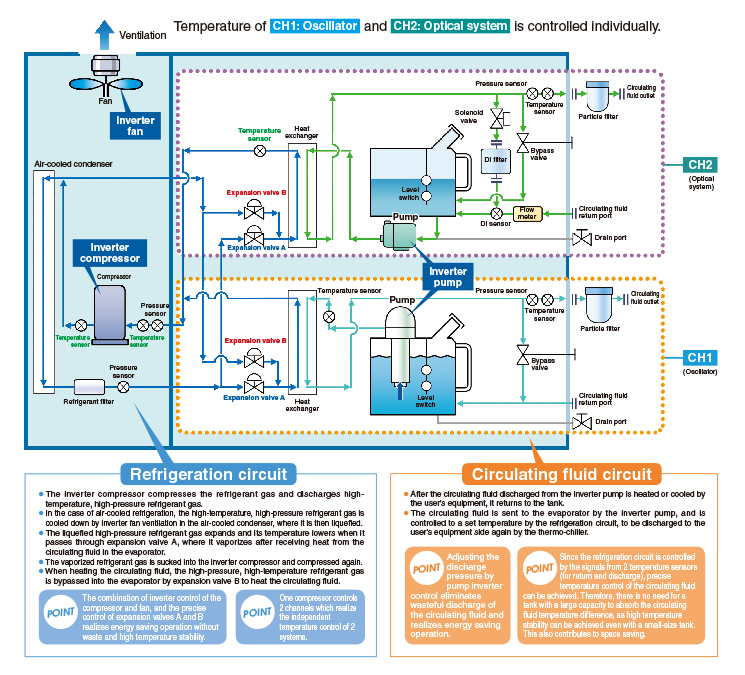

●Inverter control

The inverter respectively controls the number of motor rotations of the compressor, fan and pump depending on the load from the user’s equipment.

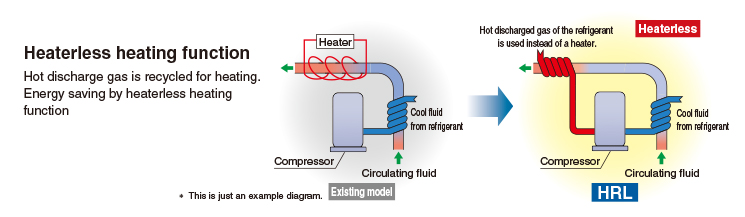

●Circulating fluid can be heated without a heater. (Circulates the hot discharged gas through expansion valve B)

One compressor controls 2 channels.

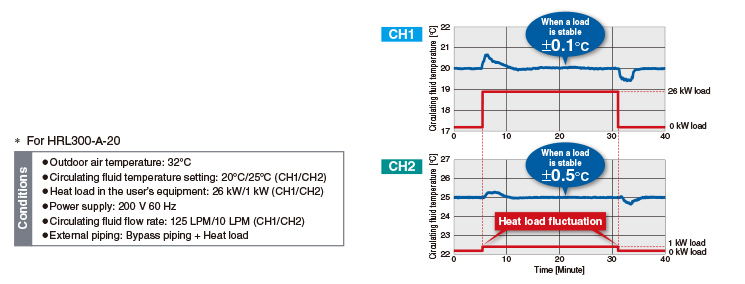

Temperature stability: ±0.1℃ (CH1) When a load is stable

By controlling the inverter compressor, inverter fan, and electronic expansion valve simultaneously, it maintains the good temperature stability when the heat load fluctuates.

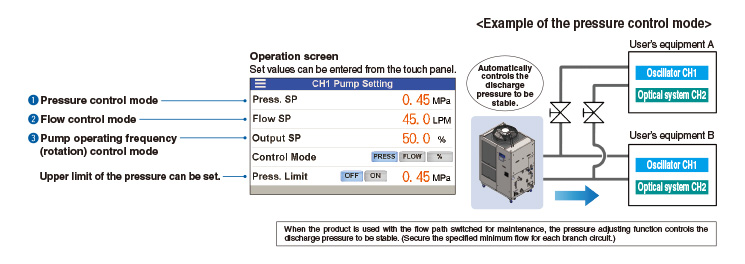

3 operation modes of the circulating fluid pump

The pump operation mode can be selected by the touch panel.

Reduced maintenance hours for the pump

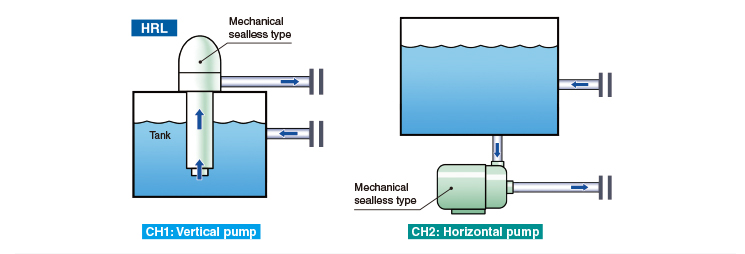

Both channels use the mechanical sealless type pump. As the pump has no external leakage of the circulating fluid, a periodic check of the pump leakage and replacement of the mechanical seal are not necessary.

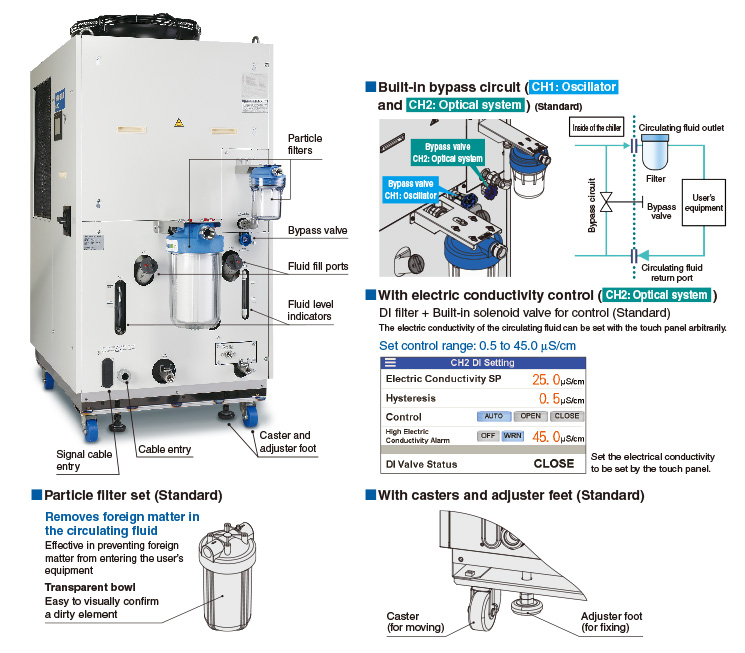

Variations

Options in demand are standardized.

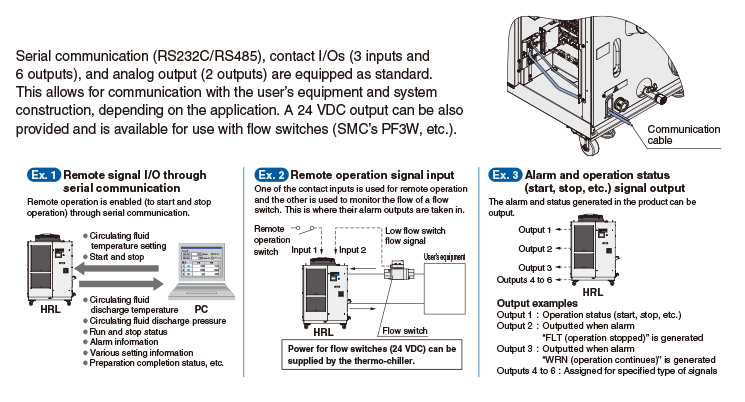

Communication functions

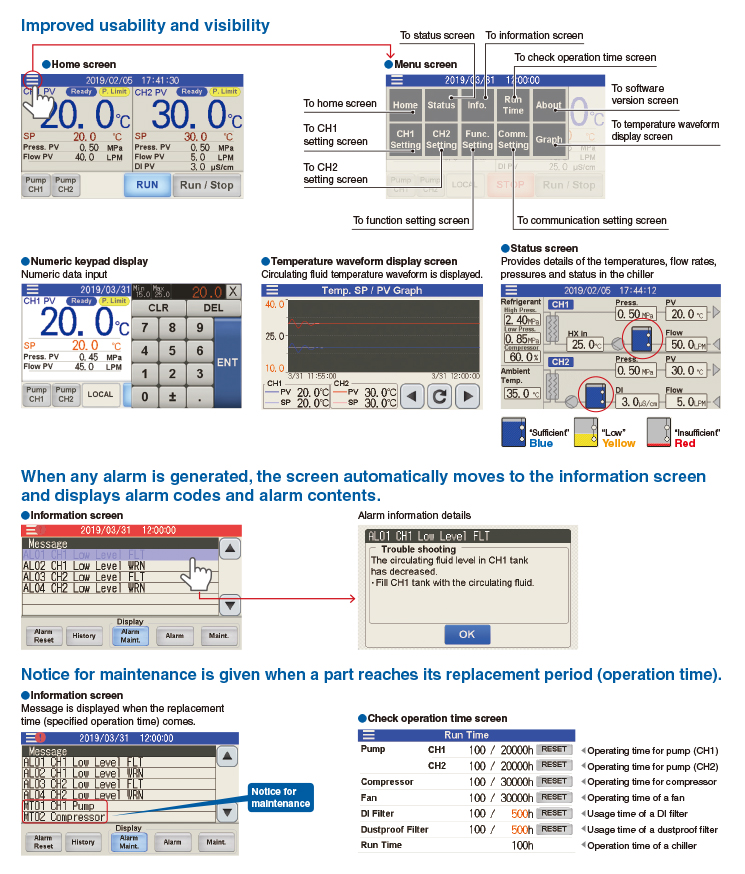

Touch panel

Global Supply Network