Static Neutralization Equipment/Ionizers

Separate Controller Ionizer/Bar Type/Nozzle Type IZT40/41/42/43

-

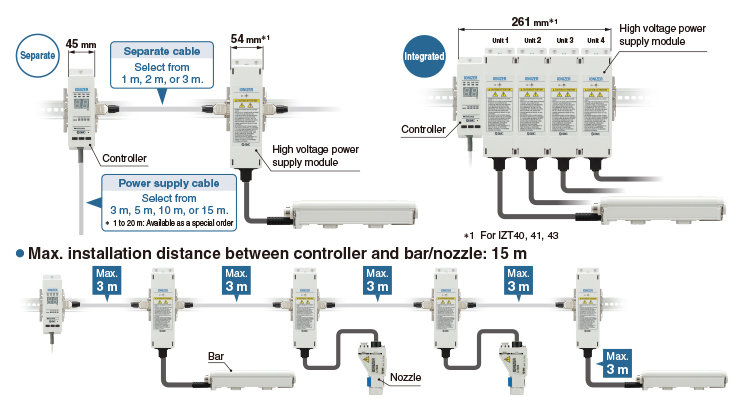

・The controller and high-voltage power supply module can be mounted separately.

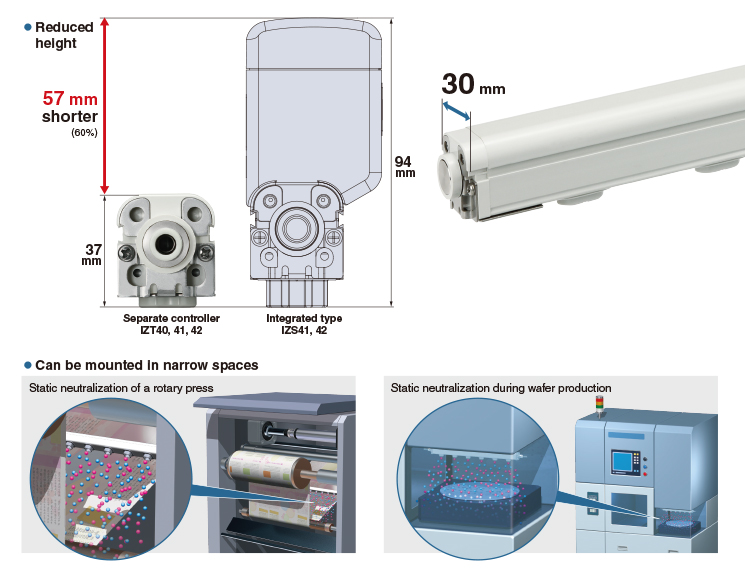

・Space saving: Height 37 mm x Width 30 mm (Bar type)

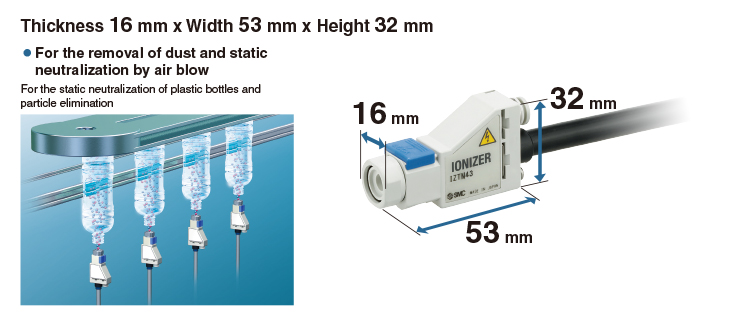

Thickness 16 mm x Width 53 mm x Height 32 mm (Nozzle type)

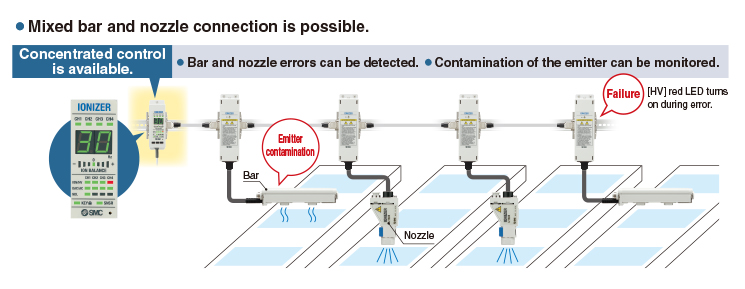

・One controller can control a maximum of 4 ionizers.

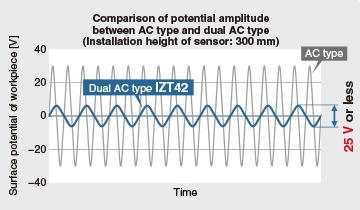

・Potential amplitude: 25 V or less

・Rapid static neutralization: Fastest time of 0.1 s

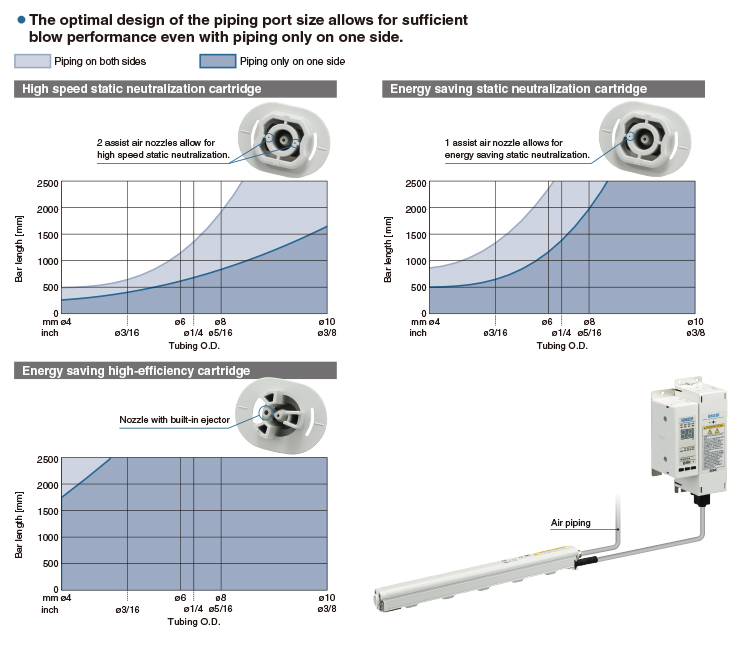

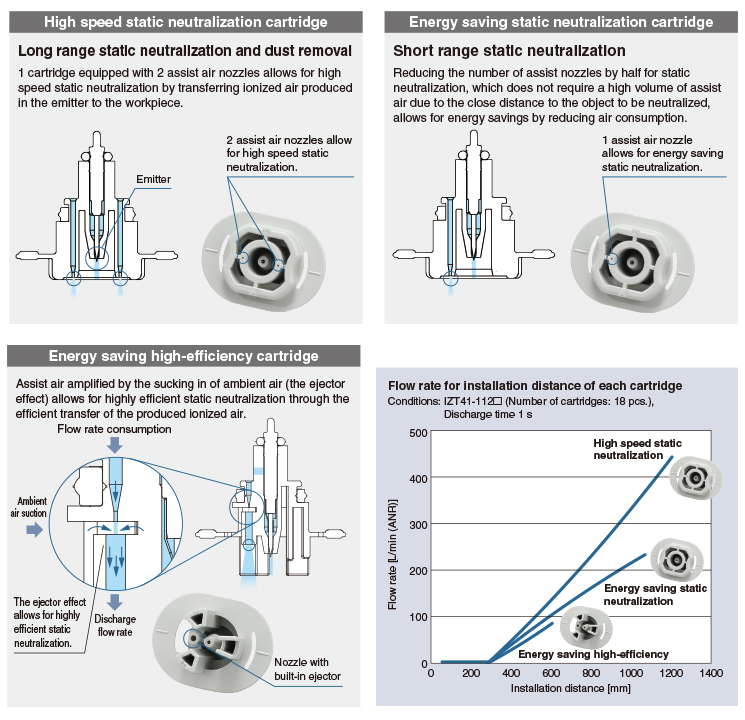

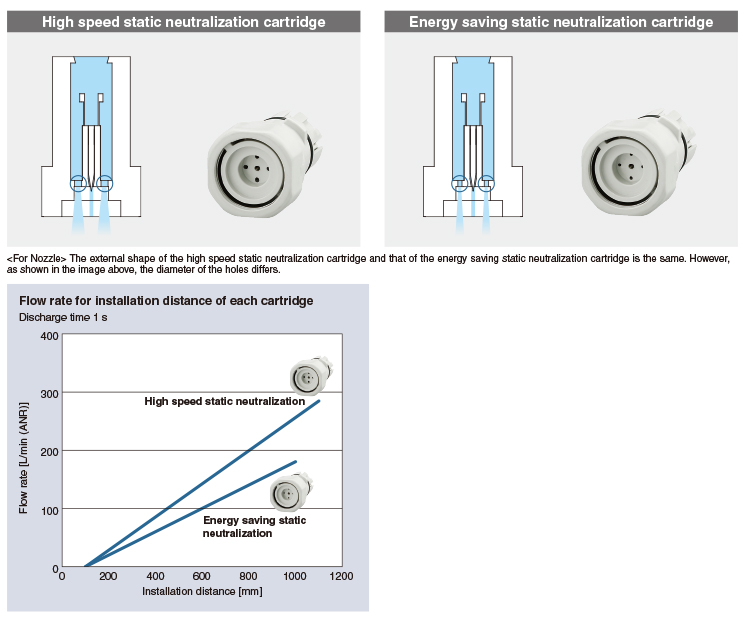

・3 types of emitter cartridges

High speed static neutralization cartridge

Energy saving static neutralization cartridge

Energy saving high-efficiency cartridge

・Static neutralization is possible even when air is not being supplied.

・IO-Link Compatible

▶IO-Link Master

| Series | Type | Ion generation method | Offset voltage (Ion balance) |

|---|---|---|---|

| IZT42(-L) Bar type |

Dual AC Type | Corona discharge type | Within ±30 V |

| IZT41(-L) Bar type |

AC Type | Corona discharge type | Within ±30 V |

| IZT40 Bar type |

Standard Type | Corona discharge type | Within ±30 V |

| IZT43(-L) Nozzle type |

AC Type | Corona discharge type | Within ±30 V |

Features

Space saving

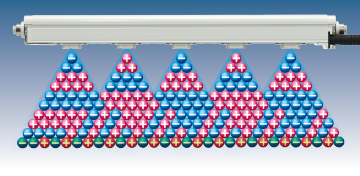

Dual AC Type IZT42 Series (Potential amplitude reduction specification)

The potential amplitude can be reduced with SMC’s original dual AC type sensor.

Static neutralization in consideration of damage to a device which is sensitive to electrostatic discharge (ESD) can be achieved.

The potential amplitude applied to the applicable workpiece is reduced even if the workpiece is mounted within close proximity of the ionizer.

-

Dual AC type IZT42

+ ions and − ions are discharged at the same time to allow the + and − ions to reach the workpiece evenly, thereby reducing the potential amplitude.

-

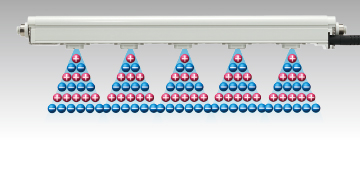

AC type IZT40, 41, 43

+ ion and − ion layers reach the workpiece alternately, which increases the potential amplitude.

-

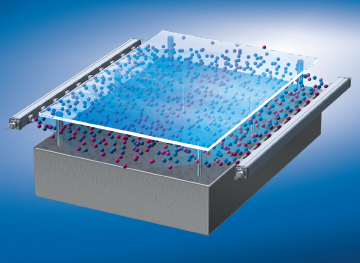

Application Examples For the static neutralization of glass substrates

Prevents the breakage of glass substrates by the static electricity generated when the substrate is lifted from the surface plate

-

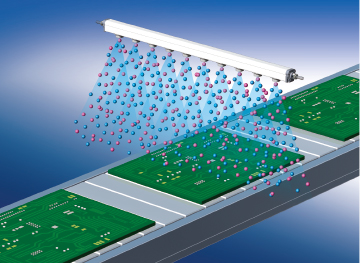

For the static neutralization of electric substrates

・Prevents element disruption due to discharge

・Prevents the adhesion of dust

Emitter contamination detection continually displayed and output

Individual ON/OFF command from an external input signal

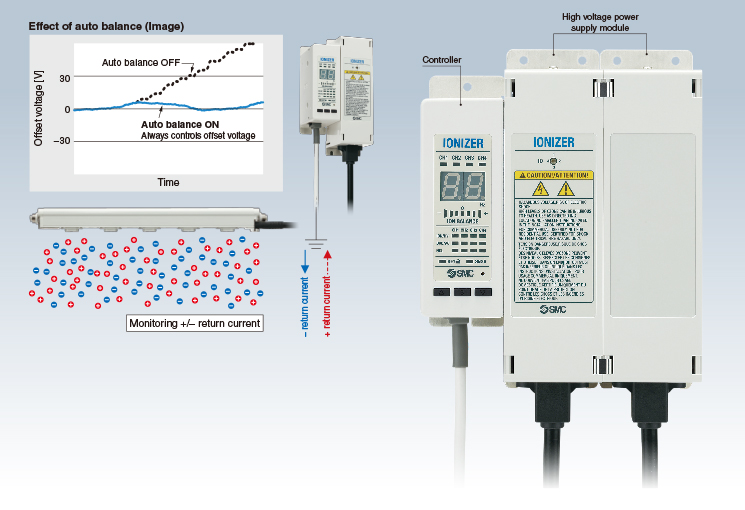

With auto balance function

The sensor is installed within the ionizer body and may be mounted anywhere.

The offset voltage (ion balance) in the static neutralization area is controlled so that the voltage is maintained at a constant value by monitoring the ions emitted from the ionizer using the ground line.

-

AC Type IZT41, 43 Series

With auto balance function

-

Standard Type IZT40 Series

Simple operation: Can be controlled by powering the ionizer ON

An AC adapter is available.

(The AC adapter can only be used for 1 ionizer.)

The compact body allows for space saving.

Space saving/Nozzle type

One controller can control a maximum of 4 ionizers./Bar type, Nozzle type

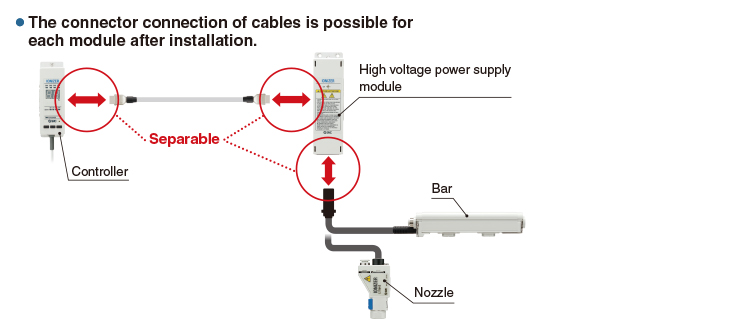

A flexible layout can be achieved due to the various module connection methods./Bar type, Nozzle type

The simple installation of each module is possible by connector connection./Bar type, Nozzle type

-

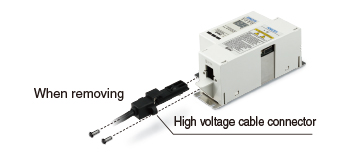

Easy insertion and removal due to connector connection/Bar type, Nozzle type

-

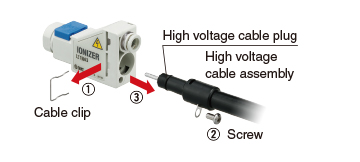

For the insertion and removal of high voltage cables/Nozzle type

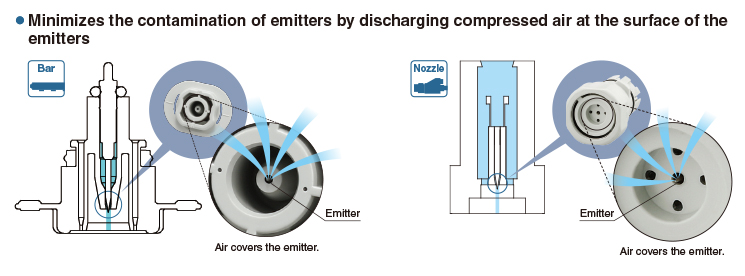

Various low maintenance cartridges can be selected according to the application./Bar type, Nozzle type

●Emitter cartridge type: For Bar

●Emitter cartridge type: For Nozzle

●Emitter material type

Air can be supplied by air piping on one side./Bar type