Product Information »

WEB Catalog

»

Air Cylinders

»

Stopper Cylinders

WEB Catalog

Product List

- Air Management System

-

Directional Control Valves

- Pilot Operated 4/5 Port Solenoid Valves

- Pilot Operated 3 Port Solenoid Valves

- Direct Operated 3/4/5 Port Solenoid Valves

- Reduced-wiring Fieldbus System (Serial Transmission System)

- Air Operated Valves

- Mechanical Valves/Transmitters

- Finger Valve/Hand Valves/Residual Relief 3 Port Valve

- Blow Guns

- Power Valves

- ISO Valves

- Explosion-Proof Valves

-

Air Cylinders

- Standard Air Cylinders (Round Type)

- Standard Air Cylinders (Square Cover)

- Compact Air Cylinders

- Environment Resistant Cylinders

- Floating Joints/Rod End

- Air-hydro Units

- Mechanically Jointed Rodless Cylinders

- Magnetically Coupled Rodless Cylinders

- Table Cylinders

- Guide Cylinders

- Dual Rod Cylinders

- Lock Cylinders/Cylinder with An End Lock

- Fine Lock Cylinders

- Specialty Cylinders

- Clamp Cylinders

- Pin Shift Cylinder

- Stopper Cylinders

- Stroke Reading Cylinders

- Valve Mounted Air Cylinders

- ISO Cylinders

- Shock Absorbers

- Auto Switches

- Actuator Position Sensor

- Rotary Actuators/Air Grippers

- Electric Actuators/Cylinders

- Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other)

- Air Preparation Equipment

- Modular F.R.L./Pressure Control Equipment

- Lubrication Equipment

- Fittings and Tubing

- Flow Control Equipment

- Silencers/Exhaust Cleaners/Blow Guns/Pressure Gauges

- Switches/Sensors/Controller

- Static Neutralization Equipment

-

Industrial Device Communication Equipment/Wireless System

- Wireless System: PROFINET Compatible Products

- Wireless System: EtherNet/IP Compatible Products

- Wireless System: IO-Link Compatible Products

- Wireless System: CC-Link Compatible

- Industrial Device Communication Equipment: PROFINET Compatible Products

- Industrial Device Communication Equipment: EtherNet/IP Compatible Products

- Industrial Device Communication Equipment: EtherCAT Compatible Products

- Industrial Device Communication Equipment: Modbus TCP Compatible Products

- Industrial Device Communication Equipment: ETHERNET POWERLINK Compatible Products

- Industrial Device Communication Equipment: CC-Link IE Field Compatible Products

- Industrial Device Communication Equipment: SSCNET III Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅲ Compatible Products

- Industrial Device Communication Equipment: PROFIsafe Compatible Products

- Industrial Device Communication Equipment: IO-Link Compatible Products

- Industrial Device Communication Equipment: PROFIBUS Compatible Products

- Industrial Device Communication Equipment: DeviceNet Compatible Products

- Industrial Device Communication Equipment: CC-Link Compatible Products

- Industrial Device Communication Equipment: AS-interface Compatible Products

- Industrial Device Communication Equipment: CANopen Compatible Products

- Industrial Device Communication Equipment: CompoNet Compatible Products

- Industrial Device Communication Equipment: Interbus Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅱ Compatible Products

- Other: RS232C Compatible Products

- Other: RS485 Compatible Products

- Process Valves

- Chemical Liquid Valves/Fittings & Needle Valves/Tubing

- Process Pumps(Diaphragm Pumps)

-

Temperature Control Equipment

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Dual Channel Thermo chiller for Lasers

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers)

- Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

- Air Temperature Controllers

- Process Gas Equipment

- High Vacuum Equipment

- Industrial Filters/Sintered Metal Elements

- Pneumatic Instrumentation Equipment

- Hydraulic Equipment

Theme

-

Clean Series/Low-Particle Generation

- Directional Control Valves

- Air Cylinders

- Rotary Actuators

- Air Grippers

- Air Dryers

- Compressed Air Cleaning Filter Series

- Clean Gas Filters/Air Filters

- Exhaust Cleaner for Clean Room/Clean Exhaust Filter

- Modular F.R./Pressure Control Equipment

- Fittings

- Tubing

- Flow Control Equipment

- Switches/Sensors

- Flow Switch

- Electric Actuators

- Fluoropolymer Equipment/PVC Equipment

-

Series Compatible with Secondary Batteries Series 25A-

- Directional Control Valves

- Actuators

- Related Products

- Rotary Actuators/Air Grippers

- Vacuum Equipment

- Air Preparation Equipment/Clean Air Filters

- ModularF.R.L./Pressure Control Equipment

- Flow Control Equipment/Fittings

- Tubings

- Detection Switches/Auto Switches

- Process Valves

- Process Gas Equipment

- Electric Actuators

- Copper, Fluorine-free Equipment Series 20-

- ISO Products

- Arc Welding Process Equipment

- IO-Link Devices

- List of ATEX Compliant Products

Stopper Cylinders

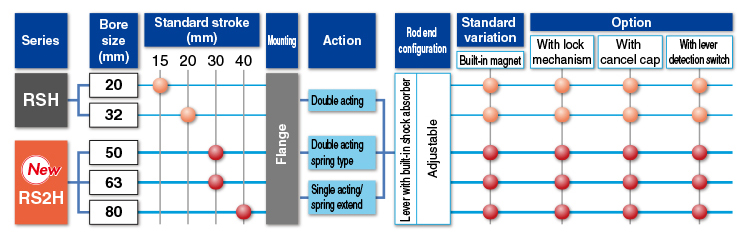

Heavy Duty Stopper Cylinder RS2H

-

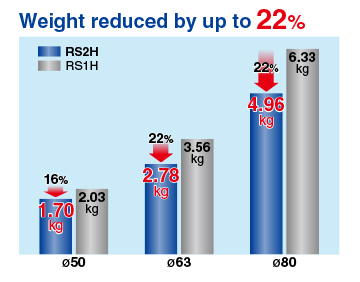

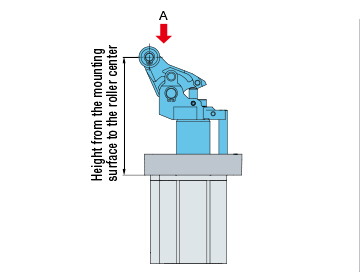

・Weight: Reduced by up to 22% (Compared with the previous RS1H series)

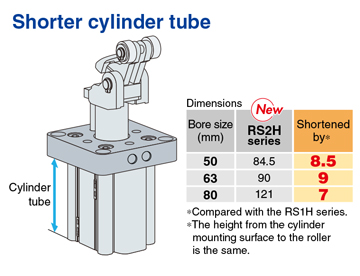

・Cylinder tube: Shortened by up to 9 mm (RS2H63-30 stroke)

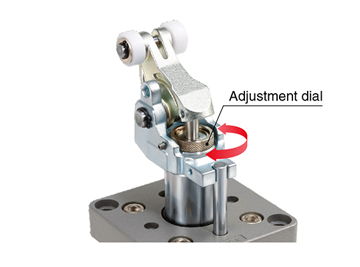

・Capable of stopping pallets softly

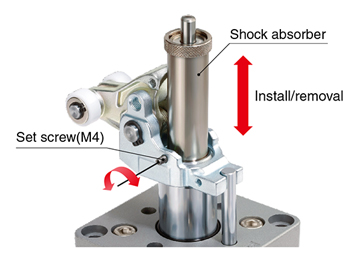

・Stopper cylinder with shock absorber

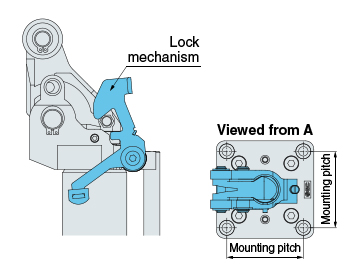

・Lock Release specification (-XC102)

-

2D/3D CAD

The new SMC CAD SYSTEM, CADENAS, allows you to output 2D/3D CAD data with full part numbers in various data formats. Responses to part number selection has been greatly improved with the newly developed system.

Click here for 2D/3D CAD2D CAD

Click here for 2D CAD -

Heavy Duty Stopper Cylinder RS2H

Manual

Type Series Action View search result Flange RS2H Double acting

Double acting with spring

Single acting, spring extendView search result -

Heavy Duty Stopper Cylinder RS2H

Symbol Specifications Download -XC102 Made to Order Common Specifications Lock Release Specification PDF

Safety Instructions

Actuators/Precautions

Auto Switches/Precautions

Model Selection/Technical Data

Made to Order Common Specifications

Green Procurement (RoHS)

| Type | Series | Action | Bore size(mm) |

|---|---|---|---|

| Flange | RS2H | Double acting Double acting with spring Single acting, spring extend |

50,63,80 |