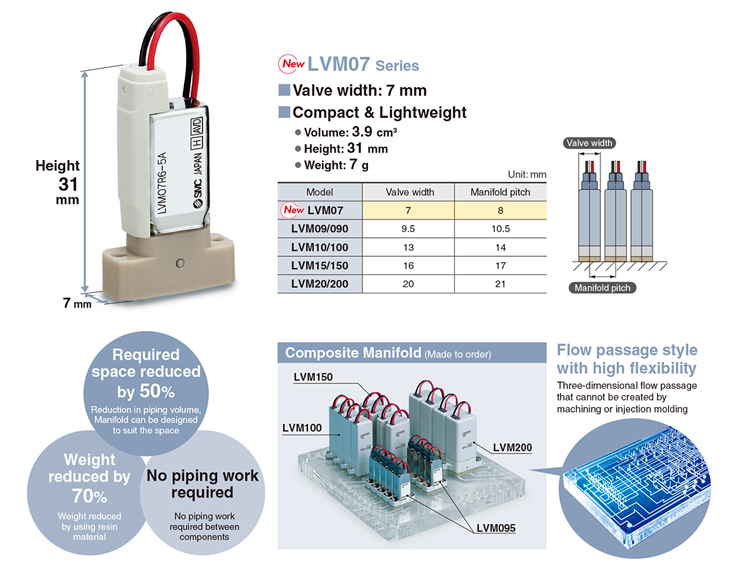

Compact 2/3 Port Solenoid Valves

Compact Direct Operated 2/3-Port Solenoid Valve for Chemical Liquids LVM

-

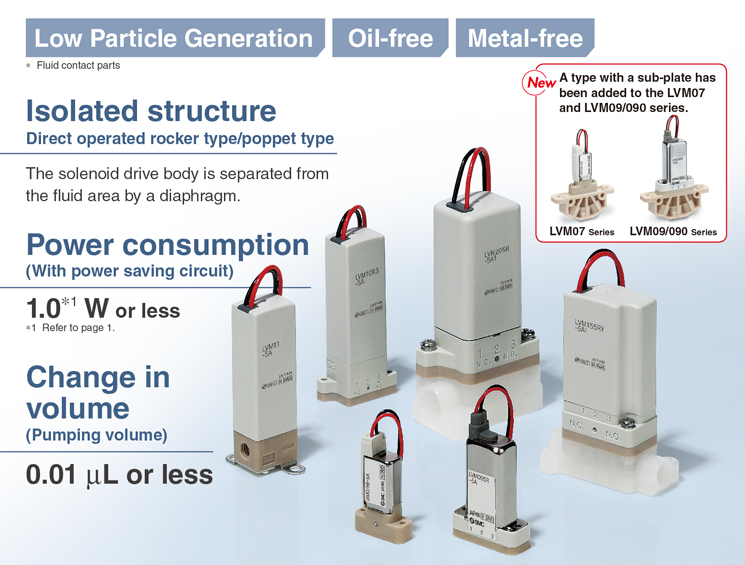

・Low particle generation, Oil-free, Metal-free * Fluid contact parts

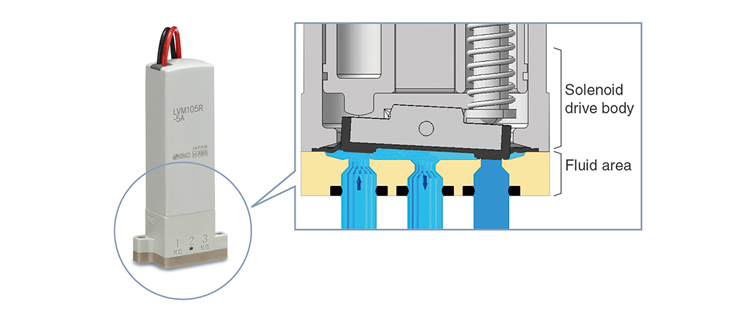

・Isolated structure

The solenoid drive body is separated from the fluid area by a diaphragm.

・Power consumption: 1.0 W or less (With power saving circuit)

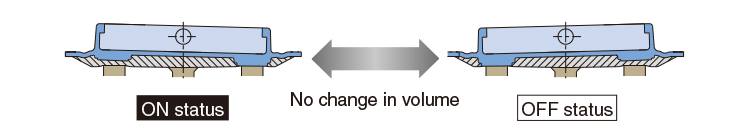

・Change in volume (Pumping volume): 0.01 µL or less

| Series | Valve construction | Valve type | Operating pressure range | Orifice diameter (mmø) |

|---|---|---|---|---|

| LVM07 Base mounted |

Direct operated rocker type | N.C. | -75 kPa to 0.1 MPa | 0.8 |

| LVM09 Body ported Base mounted |

Direct operated rocker type | N.C. N.O. Universal |

-75 kPa to 0.2 MPa | 1 (Body ported) 1.1 (Base mounted) |

| LVM10 Body ported Base mounted |

Direct operated rocker type | N.C. N.O. Universal |

-75 kPa to 0.25 MPa | 1.4 |

| LVM15 Body ported Base mounted |

Direct operated rocker type | N.C. N.O. Universal |

-75 kPa to 0.25 MPa (Max. 0.6 MPa) |

1.6 1 (High-pressure type) |

| LVM20 Body ported Base mounted |

Direct operated rocker type | N.C. N.O. Universal |

-75 kPa to 0.3 MPa (Body ported: 0.25 MPa) |

2 |

| LVM1□ Body ported Base mounted |

Direct operated poppet type | N.C. | 0 to 0.25 MPa | 1.5 |

Features

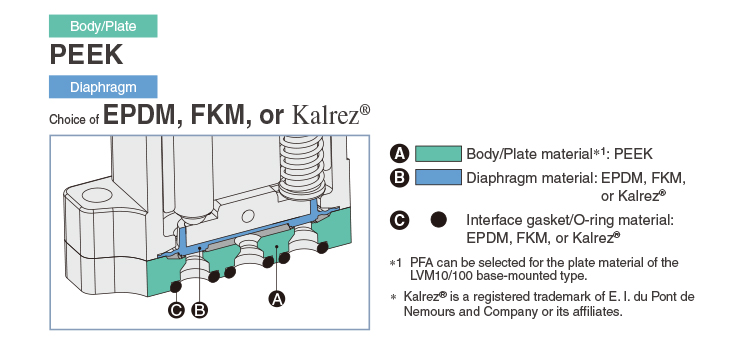

Low Particle, Generation, Oil-free Metal-free

* Fluid contact parts

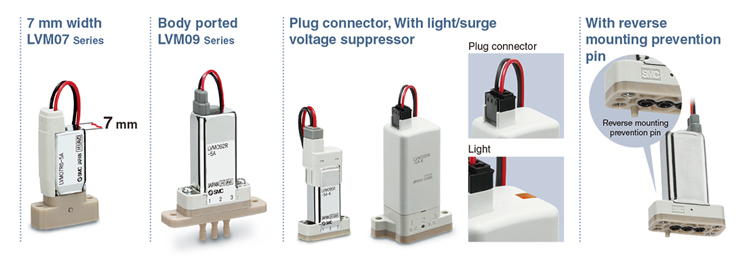

Variations/Options New

Direct Operated Rocker Type /LVM07・09/090・10/100・15/150・20/200

・Isolated structur

The solenoid drive body is separated from the fluid area by a diaphragm.

・Fluid contact material (Metal-free)

・Change in volume (Pumping volume): 0.01 μL or less

With a normal diaphragm valve, because the valve chamber volume varies depending on the ON or OFF status, the difference in volume is discharged into the outlet side of the valve when the valve is switched from ON to OFF.

However, with a rocker type valve, there is almost no change in volume, and thus no fluid is discharged into the outlet side of the valve.

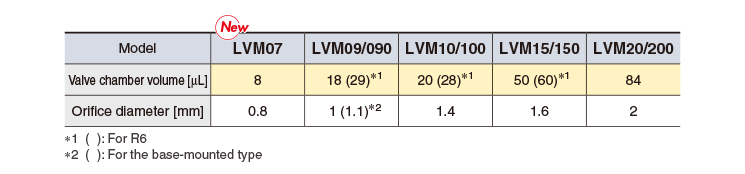

・Valve chamber volume

Residual liquid is reduced by suppressing the valve chamber volume.

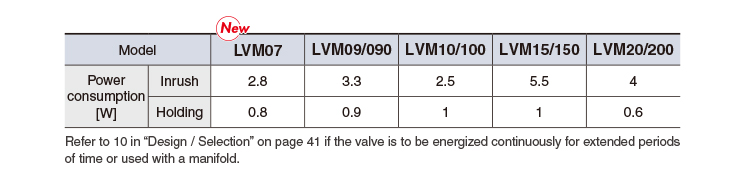

・A type with a power saving circuit can be selected.

Holding power consumption can be reduced substantially.

Continuous energization for extended periods of time is possible.

Space saving